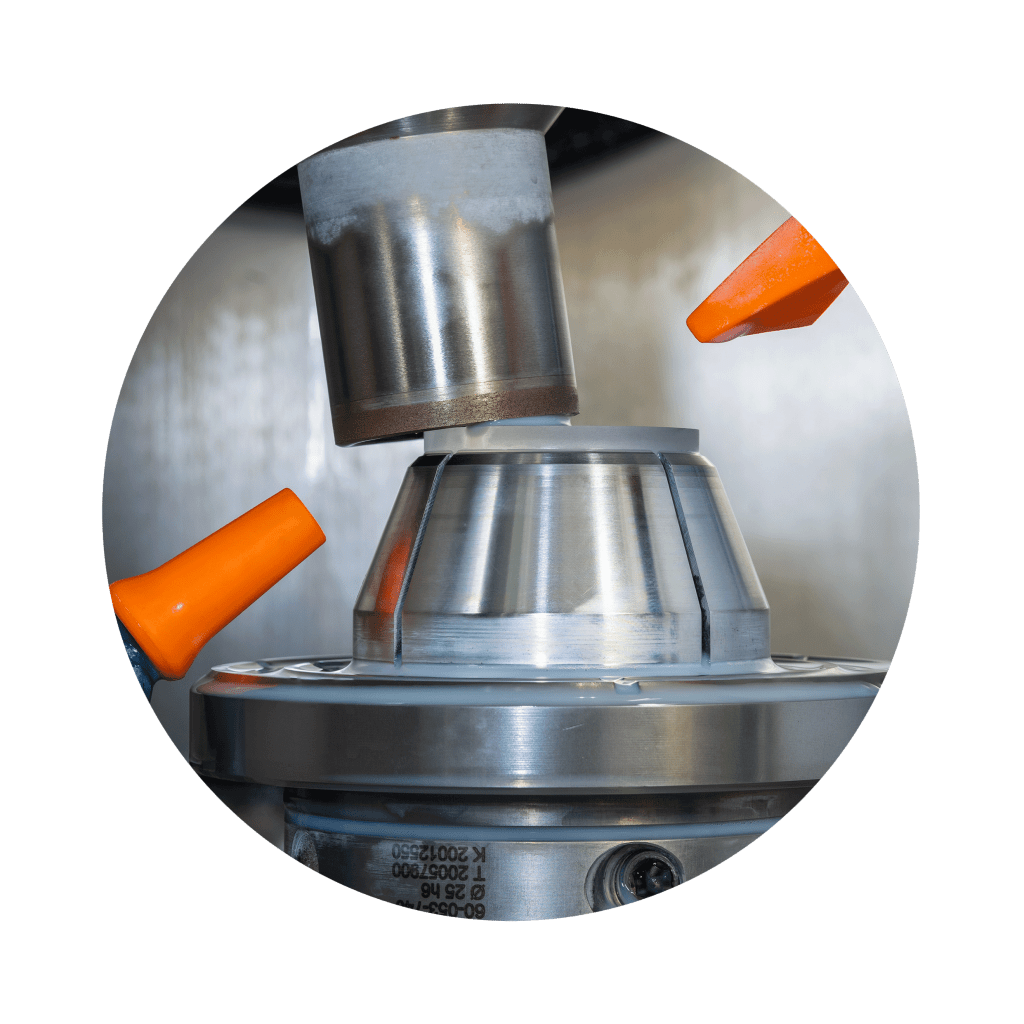

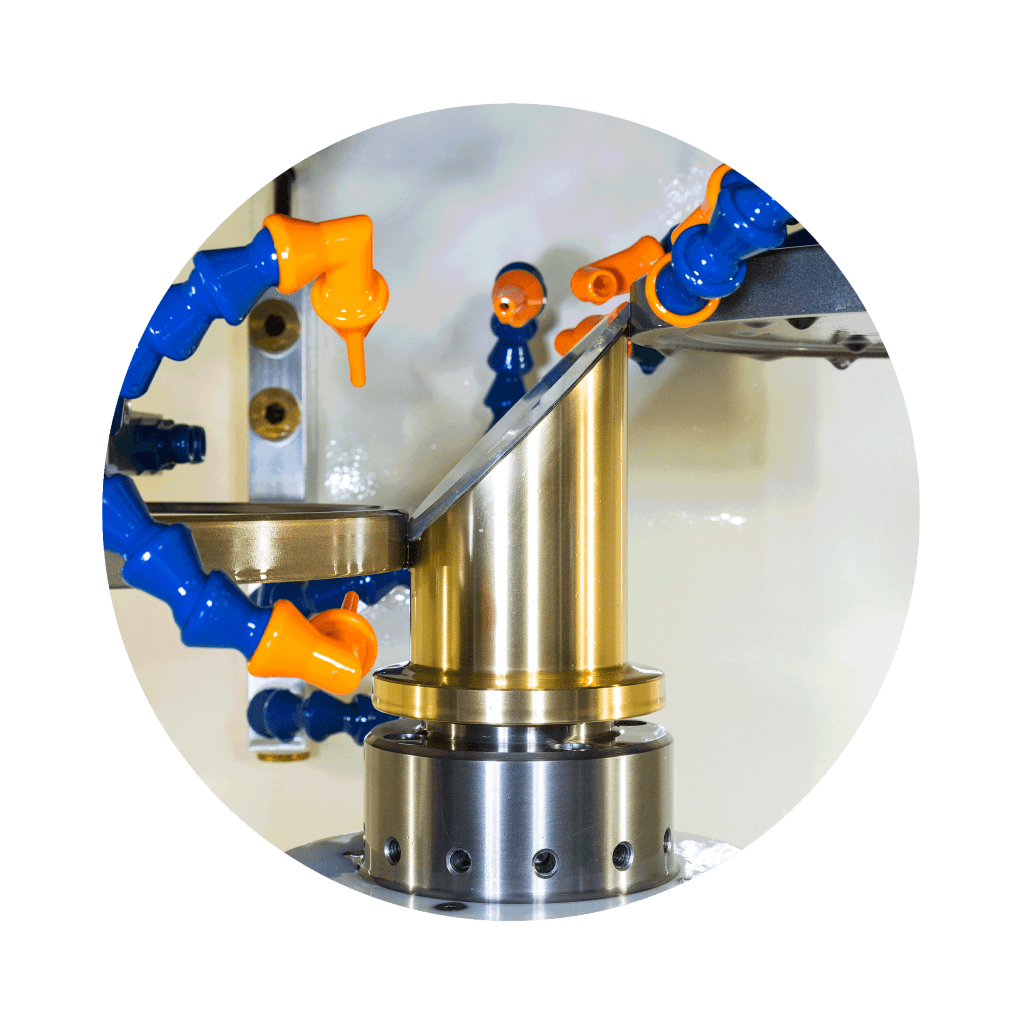

The radii of the lenses are pre-ground and finely ground with diamond cup tools of different grain size and concentration.

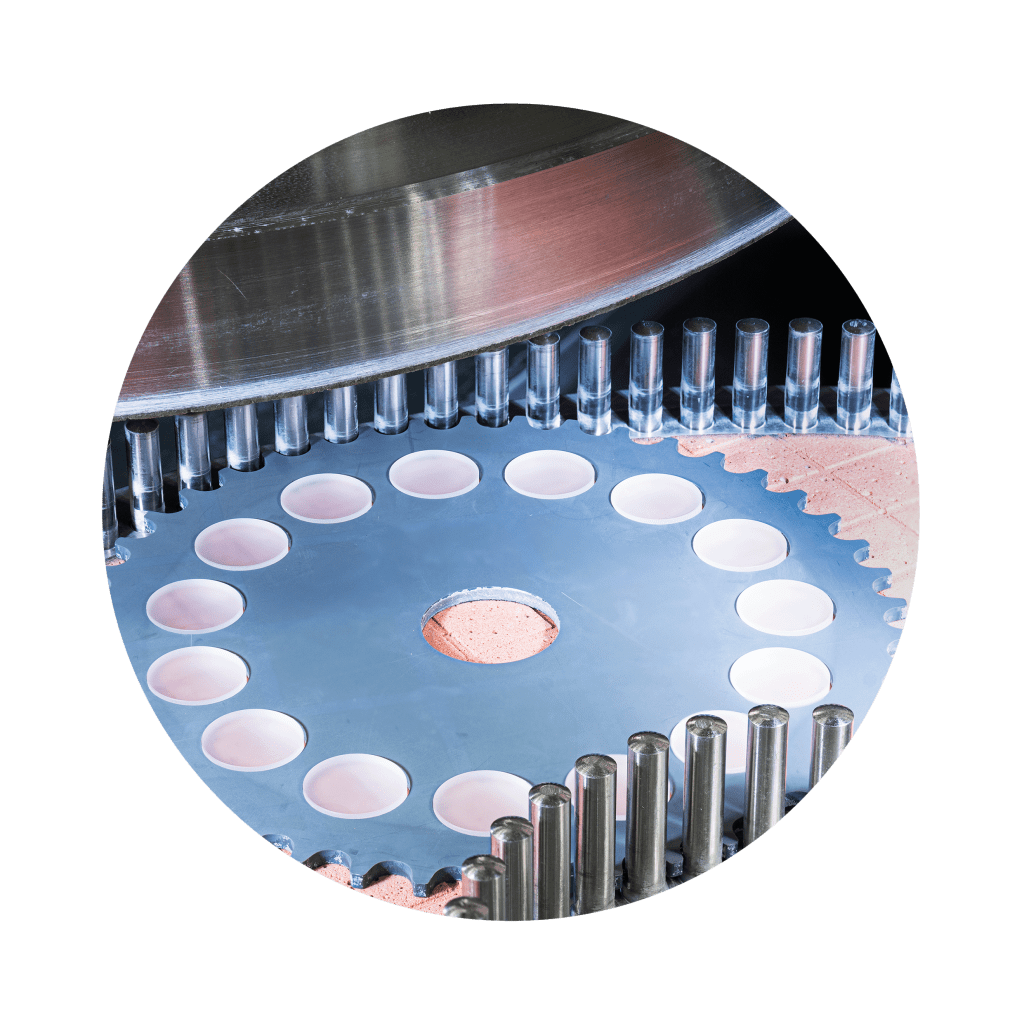

Especially sensitive optical glasses require a shortening of the polishing process. For this reason, after pre-grinding and fine grinding, ultra-fine grinding is carried out with a calotte tool studded with diamond pellets.

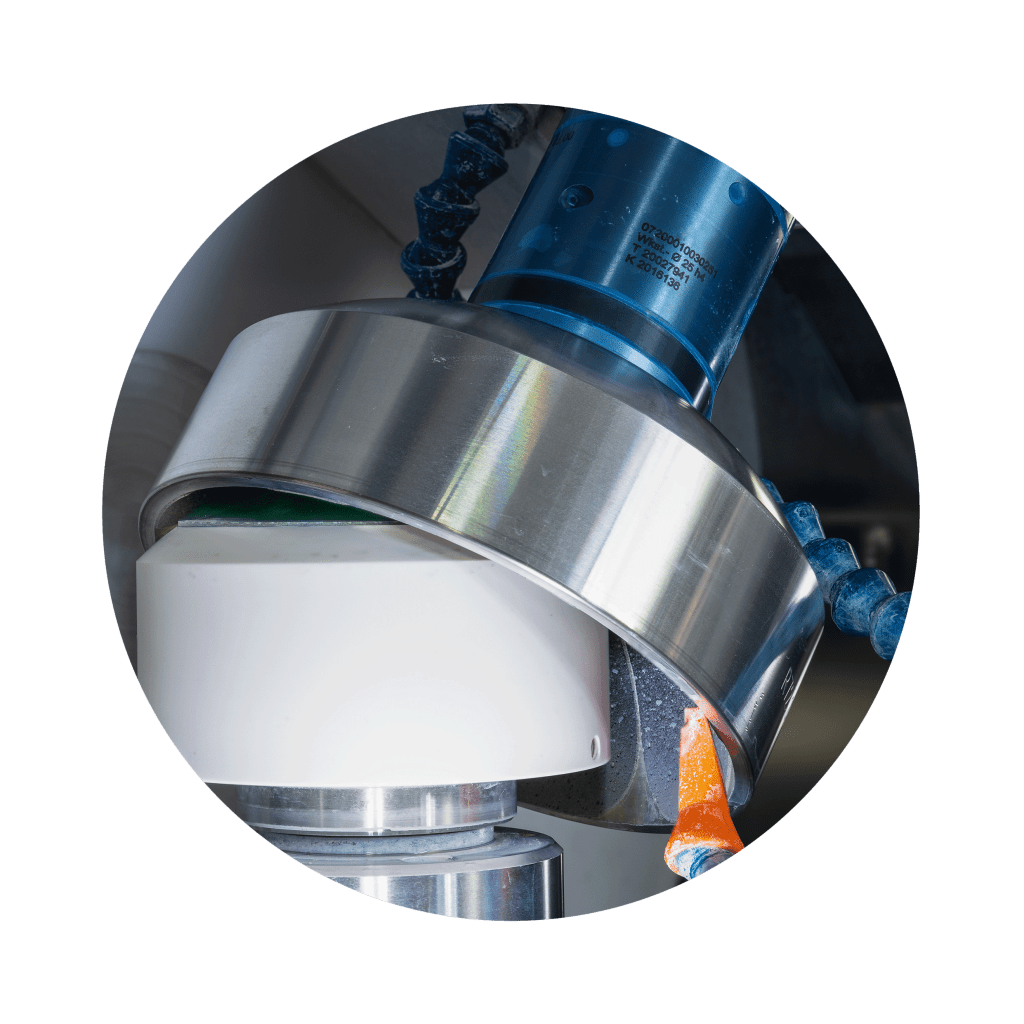

The supreme discipline in precision optics is the polishing of precision optical components. In this mechanical-chemical-thermal process, the opaque, finely or superfine ground surfaces become transparent. Here, particular attention must be paid to the conformity to the specified surface form and surface imperfection.

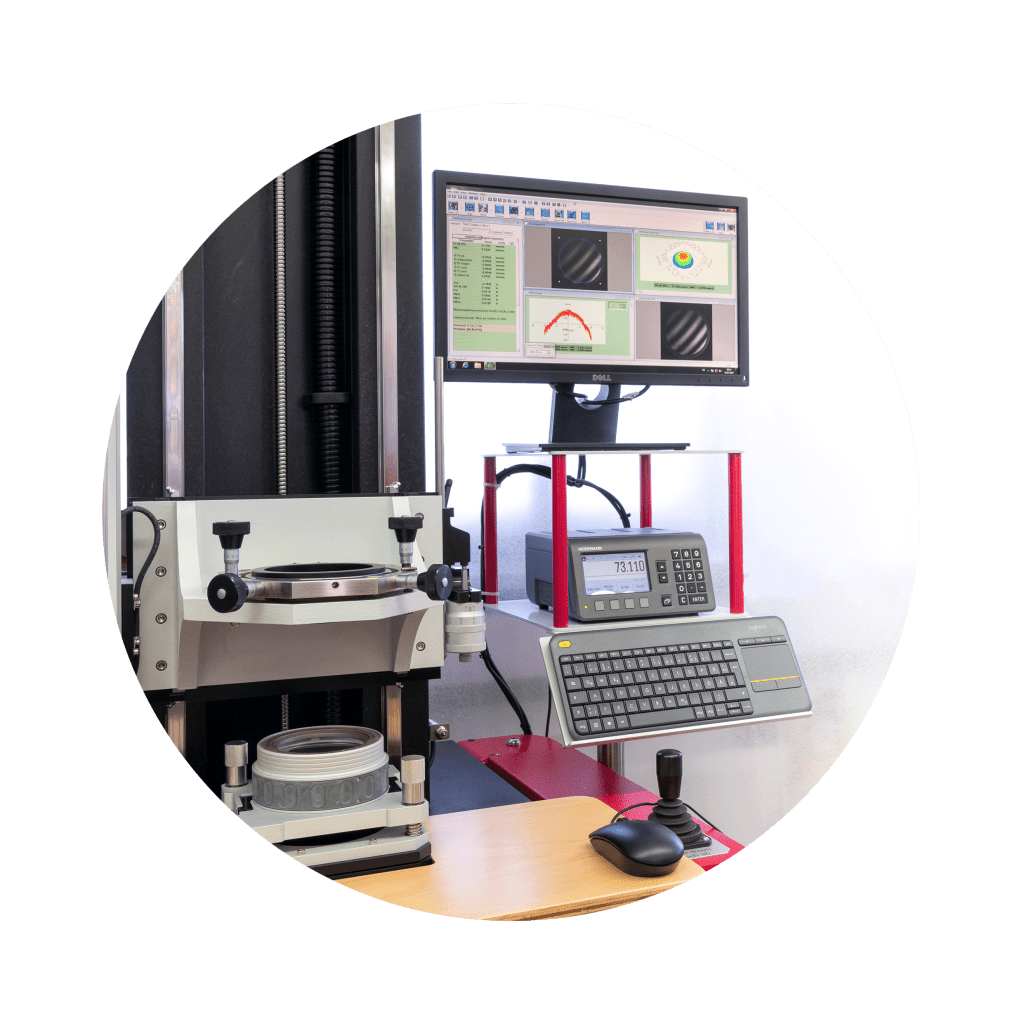

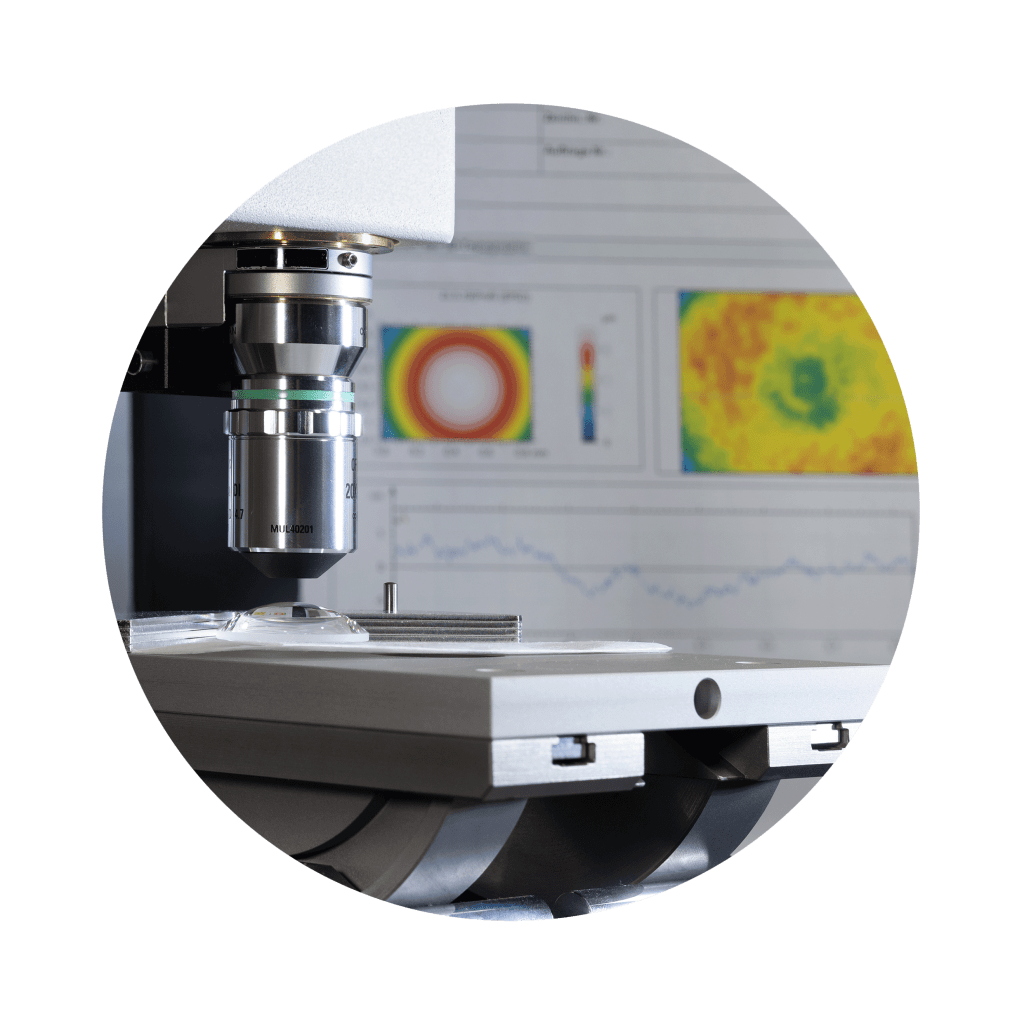

Immediately after polishing, the surface form can be measured on interferometers with 4″ measuring lenses of different apertures.

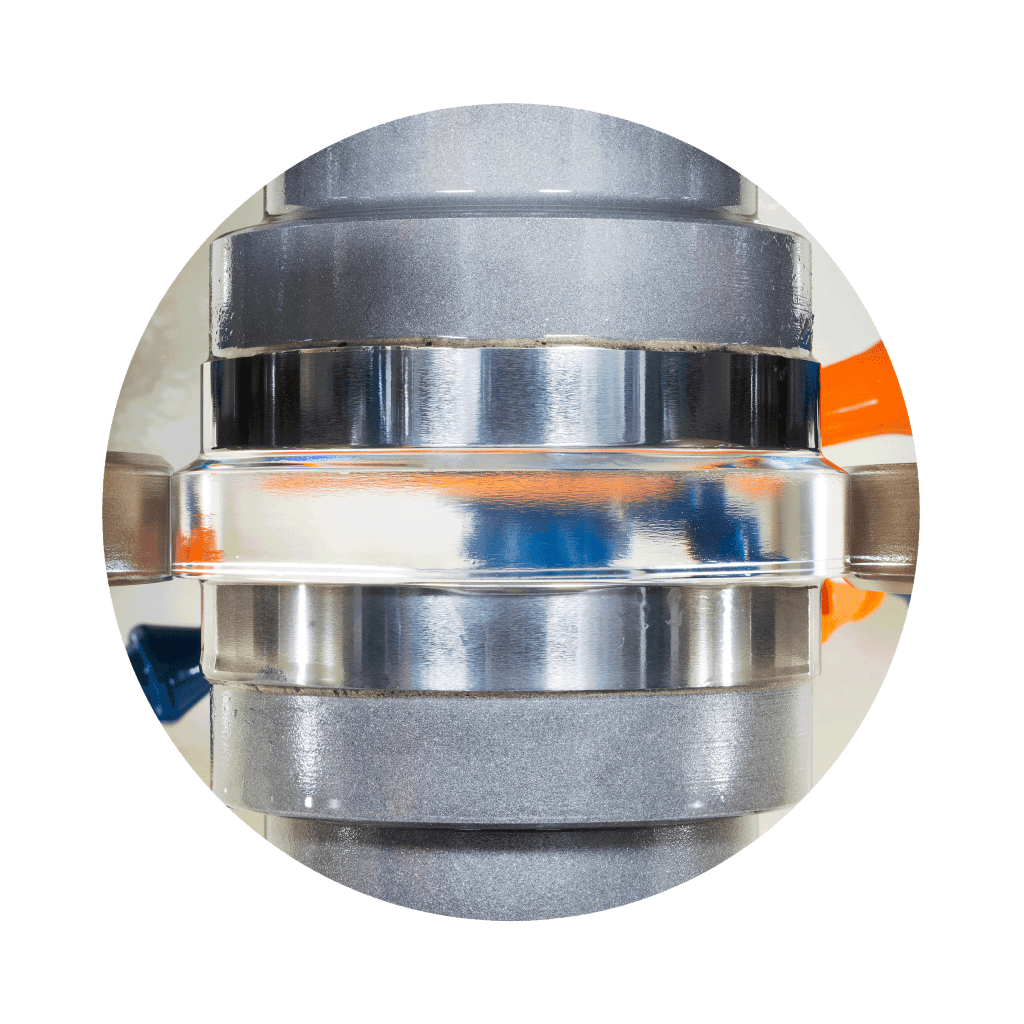

This process is used to grind and polish the front and rear sides of plane-parallel parts simultaneously. This allows excellent surface form tolerance and parallelism to be achieved even on thin substrates.

This device is used to measure the surface texture (polishing degree P1 to P4). Rq values smaller than one nanometer are achievable.

The polishing degree can be measured on both flat and spherical surfaces.

Elliptical plates with right-angled edge cylinder or under 45° (Brewster window) are produced on modern CNC machines.

The CNC centring technology enables us to produce any desired outer contour for lenses and to achieve centring accuracies of well under half a minute. Whether flat or radius chamfer, step or angle – thanks to this technology, any external shape of a lens can be produced without additional tooling costs.

CNC machines are used to produce precisely fitting holes without edge chips in polished or coated lenses.

The centring accuracy of the lenses can be checked using a laser centring test and cementing device. This device can also be used for high-precision cementing of lenses with UV adhesive.

Permanent quality assurance is the guarantee for satisfied customers. Our extensive testing equipment enables us to measure lenses, objectives, thin films etc. exactly.

We regularly train young people to become precision opticians.

In 2019, for example, our trainee completed her apprenticeship as the best of their year in the IHK Chamber of Commerce district of Munich and Upper Bavaria with very good results.